Shigley’s Mechanical Engineering Design Solutions has long been a cornerstone in the field, providing engineers with a comprehensive framework for designing and analyzing mechanical components. This guide explores the key concepts, principles, and methodologies that underpin Shigley’s solutions, empowering engineers to create robust and efficient designs.

From stress analysis to material selection, Shigley’s approach encompasses a wide range of topics essential for mechanical engineering design. This guide delves into the intricacies of each aspect, providing a thorough understanding of the factors that influence design decisions.

1. Shigley’s Mechanical Engineering Design Solutions Overview

Shigley’s Mechanical Engineering Design Solutions is a comprehensive reference for mechanical engineers, providing guidance on the design and analysis of machine elements and systems. It covers fundamental concepts, design methodologies, and practical applications, making it an indispensable resource for professionals in the field.

First published in 1943, Shigley’s has evolved over the years to incorporate the latest advancements in mechanical engineering. It has become a standard textbook for engineering students and a trusted reference for practicing engineers.

2. Key Concepts and Principles: Shigley’s Mechanical Engineering Design Solutions

Shigley’s design solutions are based on the fundamental principles of mechanics, materials science, and engineering analysis. Key concepts include:

- Stress analysis: Determining the distribution and magnitude of stresses within a component or system.

- Fatigue: Understanding the effects of repeated loading on material properties and component durability.

- Failure modes: Identifying the different ways in which components can fail, including fracture, yielding, and buckling.

- Material selection: Choosing the appropriate material for a specific application based on its strength, durability, and cost.

3. Design Process and Methodologies

Shigley’s recommends a systematic design process that involves:

- Problem definition: Clearly stating the design requirements and constraints.

- Concept generation: Brainstorming and evaluating potential design solutions.

- Analysis: Using analytical methods and simulations to assess the performance of design concepts.

- Optimization: Iteratively refining the design to meet performance requirements and minimize cost.

Shigley’s also introduces various design methodologies, such as:

- Finite element analysis (FEA): A numerical technique for solving complex stress analysis problems.

- Computer-aided design (CAD): A software tool for creating and analyzing 3D models of components and assemblies.

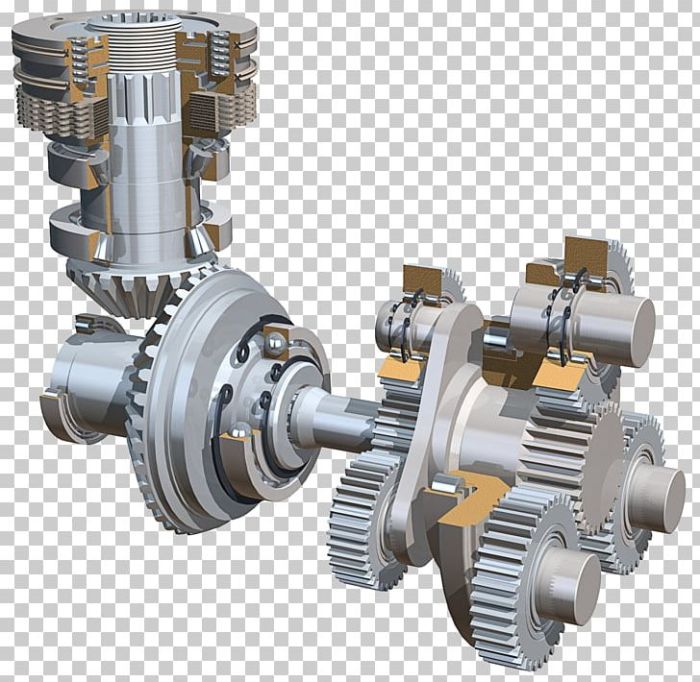

4. Components and Machine Elements

Shigley’s covers a wide range of components and machine elements, including:

- Bearings: Supporting and guiding rotating shafts.

- Gears: Transmitting power and motion between shafts.

- Shafts: Connecting components and transmitting torque.

- Springs: Storing and releasing energy.

Shigley’s provides detailed information on the design, analysis, and selection of these elements, with examples of their applications in real-world engineering systems.

5. Materials and Manufacturing Considerations

Shigley’s emphasizes the importance of material selection in mechanical engineering design. Factors to consider include:

- Strength: Ability to withstand applied loads without failure.

- Durability: Resistance to wear and fatigue over time.

- Cost: Availability and affordability of the material.

Shigley’s also discusses various manufacturing processes and their impact on design decisions, such as:

- Casting: Forming components by pouring molten metal into a mold.

- Forging: Shaping metal by hammering or pressing it.

- Machining: Removing material from a workpiece using cutting tools.

6. Case Studies and Applications

Shigley’s includes numerous case studies and examples that illustrate how its design solutions have been applied in real-world engineering projects. These examples highlight:

- Successful designs: Demonstrating the effectiveness of Shigley’s principles.

- Lessons learned: Sharing insights from both successful and unsuccessful designs.

- Challenges faced: Outlining the obstacles encountered and how they were overcome.

7. Emerging Trends and Future Directions

Shigley’s recognizes the rapid advancements in mechanical engineering design and discusses emerging trends, including:

- Additive manufacturing (3D printing): Creating complex shapes directly from digital models.

- Smart materials: Materials that can respond to external stimuli, such as temperature or stress.

- Data-driven design: Using data analysis to optimize designs and predict performance.

Shigley’s is continually adapting to these changes, incorporating new technologies and methodologies into its design solutions.

Answers to Common Questions

What is the purpose of Shigley’s Mechanical Engineering Design Solutions?

Shigley’s Mechanical Engineering Design Solutions provides a comprehensive framework for designing and analyzing mechanical components, ensuring their strength, durability, and efficiency.

What are the key principles underpinning Shigley’s design solutions?

Shigley’s solutions are based on fundamental principles of mechanics, including stress analysis, fatigue, failure modes, and material selection.

How does Shigley’s approach to design differ from others?

Shigley’s solutions emphasize a systematic and iterative design process, involving problem definition, concept generation, analysis, and optimization.